Montanari has developed a fully automatic system that can track linen moving through the washing and ironing stages with the utmost accuracy, which also simplifies the counting processes, monitors the working life of the items, manages returns, and processes statistics of all kinds.

Employing this innovative yet tried-and-tested Radio Frequency Identification system, the tunnel can count large amounts of linen automatically and simultaneously. The linen placed on the piece counter conveyor system is taken inside the tunnel, where it is then identified using radio wave technology.

Features:

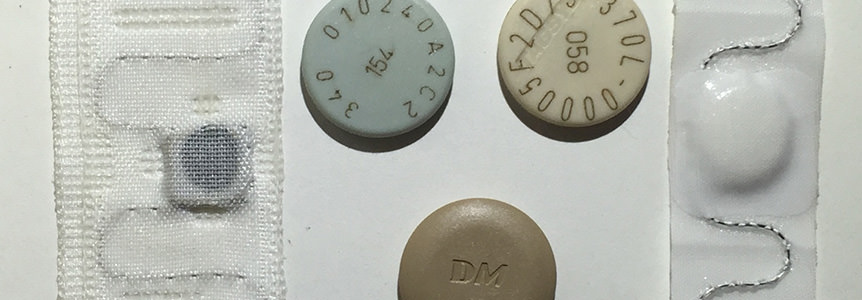

- System based on a microtransmitter inserted in the linen, which is programmed to contain a series of data and information about the item’s processing route and facilitate the issue of notes/invoices;

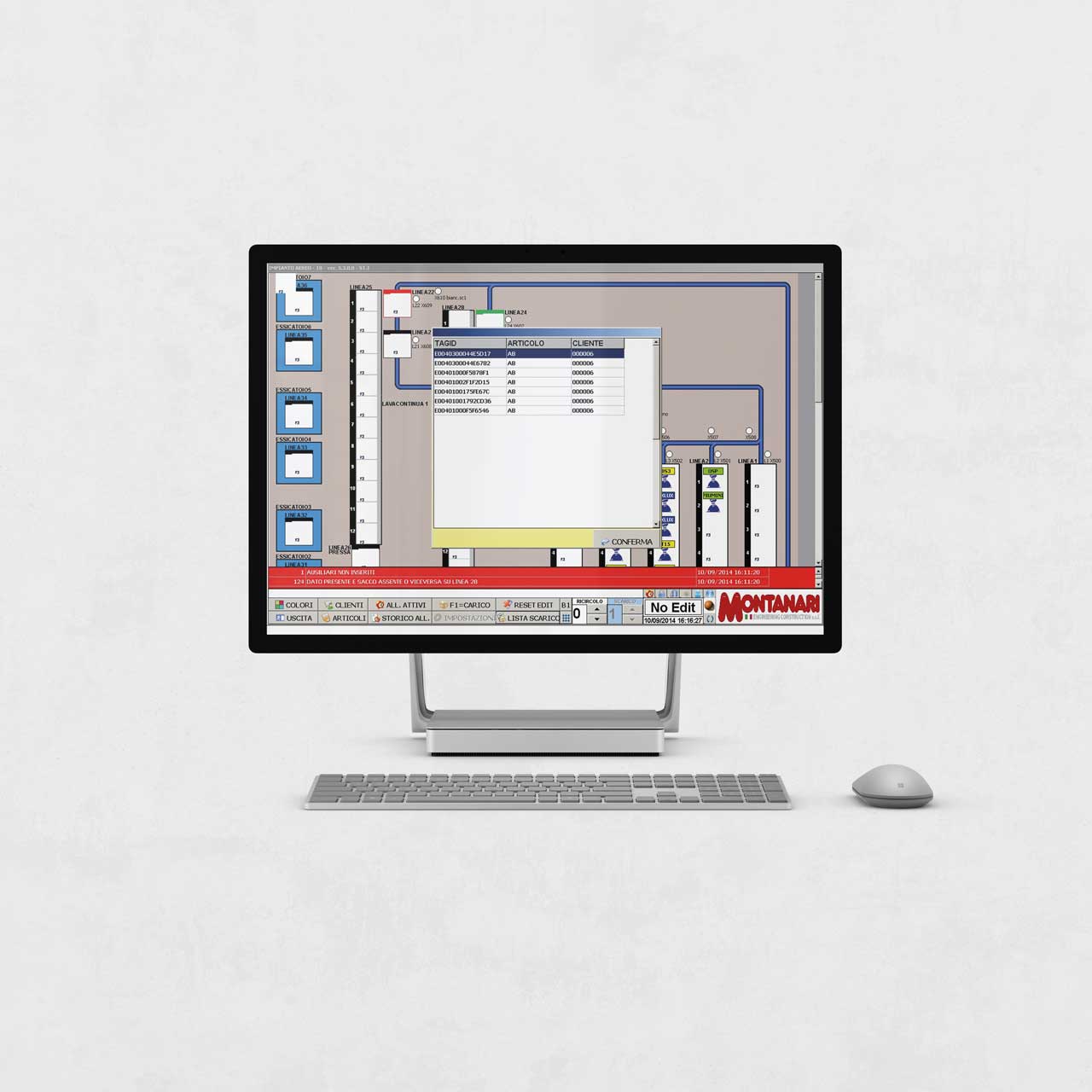

- Recognition of tags/chips via an RFID recognition system and dedicated ERP software;

Who it is aimed at:

- Laundries that handle large quantities of linen and different kinds of items;

- Customers with a high level of automation.