Special version with mixed mode electric and steam.

Production: available in 3 models up to 12, 15 and 22 packs per minute, depending on product size and film thickness Max packet size: depending on film width (item base + height: 900 mm.)

Film to be used To use with PE shrink lm Weldable lm thickness: 35/120 mM Diam. max usable coil: 300 mm. Max width: 900 mm.

The machine, with steel frame painted, consists of:

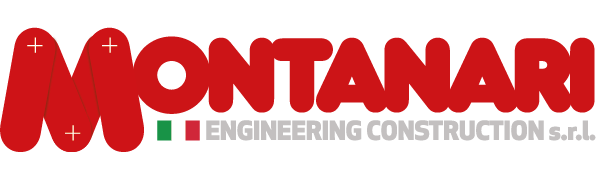

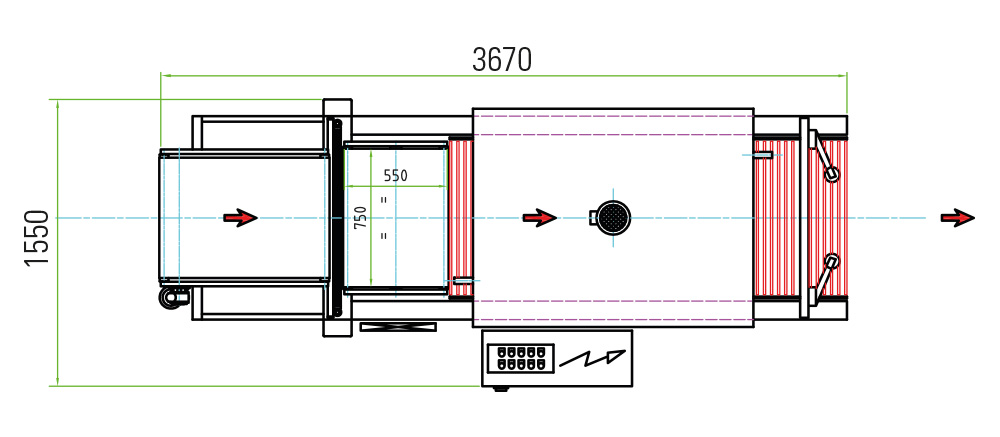

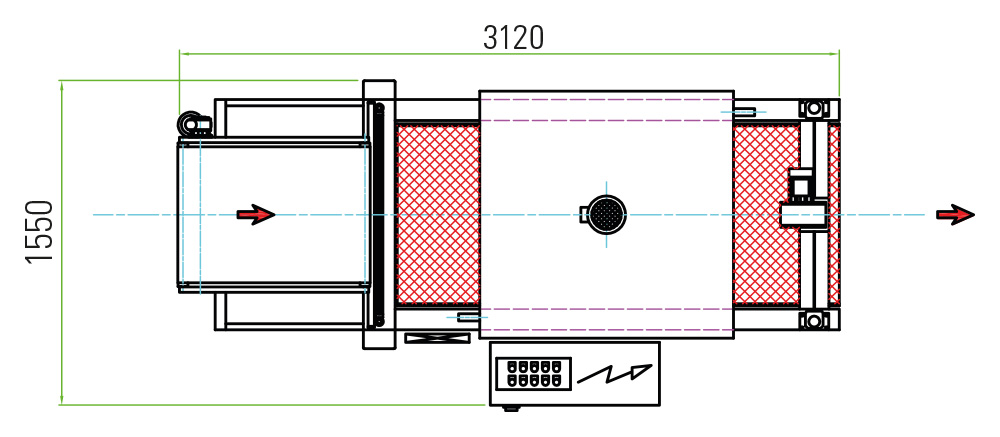

- Supply tape mm. 870 x 650 motor with adjustable speed with inverter. Device with pneumatic movement of the tape forward / backward to facilitate the passage of the pack over the sealing bar.

- Photocells for reading product and management of the packing cycle.

- Upper and lower film feed motor with end film alarm.

- Dragging plastic roll placed on the roller feed conveyor to facilitate the performance of the film and the passage of very light products.

- Pneumatic sealing bar mm. 950 for heating cutting and welding film with Teflon insert with adjustable temperature from the control panel.

- Film usable range: max. mm. 900

- Maximum product height : mm. 380

- Pneumatic sealing product over the bar with pressure regulator and height adjustment.

- Conveyor belt tunnel with Teflon net : W = 830 mm. – with adjustable speed with inverter.

- Shrink tunnel with hood size: L=1200 x W=900 x H=420 mm.

- Tunnel with mixed heating with electrical heaters (12 kW) and heat exchanger steam. Steam connection input 1” and output ¾”.

- Max pressure steam plant 18 bar.

- Temperature inside the tunnel appears and adjustable temperature control place on the electrical panel. Max 200 ° / 220 ° C.

- Paving-side rolls mounted at tunnel exit.

- Control panel with PLC and operator panel that display anomalies.

- Protective equipment as per EC safety rules.

- Machine mounted on feet.

Possible user mode

Special machine for the laundry industry, suitable for the packing of different sizes. The machine is equipped with a heat exchanger that allows the use of steam – connecting the same to the existing production equipment, reducing the consumption of electric energy.

TECHNICAL DATA

Worktop height mm. 850 (+ – 50 mm.)

Colour machine Gray RAL 7035 – blue RAL 5005

Main voltage 400 V AC – 50 Hz. + N

Auxiliary voltage 24 V. dc

Installed power resistors 12 kW + steam = 15 kW or just electric power= 16,5 kW Total: 19.5 kW

Compressed air supply 6 bar

Compressed air consumption 16 Nl/cycle

Max pressure 18 bar steam plant

Steam inlet connection 1”

Steam outlet connection ¾”

Documentation Wiring diagram User manual Parts list Print program